Cyclone 2-Stage Dust Collectors

POWERTEC on May 17th 2022

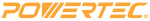

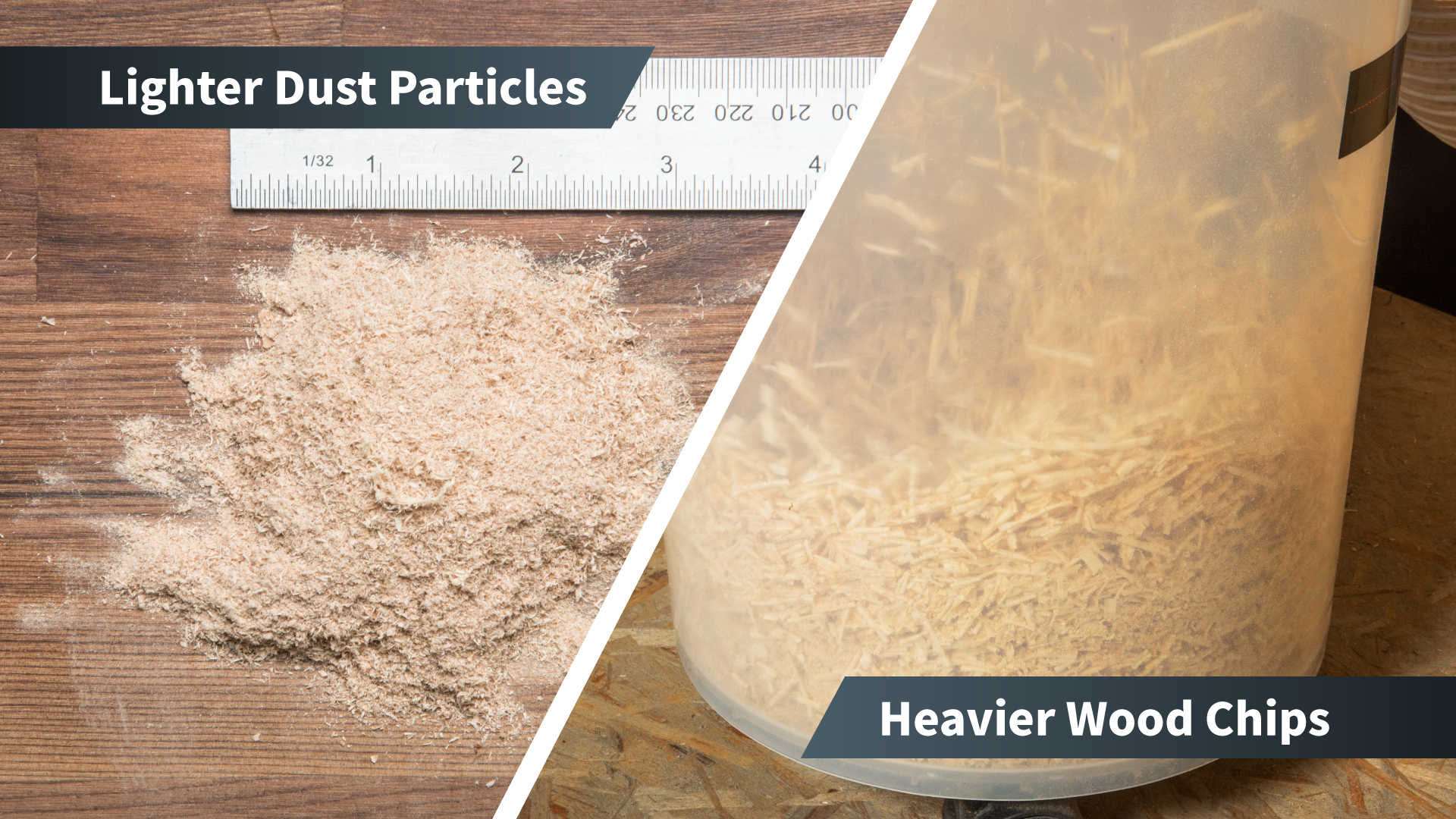

A cyclone separates heavy dust debris and fine-particle dust before they enter your dust collector. Heavy dust particles stay in the cyclone while the lighter, fine-particle debris moves on to your dust filter.

It’s the first part of a two-stage dust collector system; woodchips, wood slivers, sawdust, etc., can now be easily collected and disposed of without having to play with a messy filter bag every time it fills up. The dangerous stuff, fine-particle dust, moves on and gets collected in the filter bag.

Why use a cyclone? To save time, money, and your health. With the cyclone in place, the vast majority (60% or more) of workshop debris coming off your table saw, bandsaw, etc. gets collected in the cyclone. Now, those expensive filter bags don’t need to be changed as often. It also means less mechanical pressure on your collector and much less work for your filters, extending the life of both.

If you’ve spent money on 0.5-micron filter, you’ll know just how expensive they are to replace, and how fragile they are. A tiny hole made by a loose screw or a sharp woodchip and the filter is rendered useless – and just to recap: no one wants to be breathing in superfine particles of wood dust, leaded paint, varnish, mold… With the cyclone, only fine-particle dust hits the dust filter, helping to keep it intact.

As for the debris that collects in the cyclone, the chips, slivers, and sawdust. Pour it into a garbage bag and dump with the trash. The main thing to watch for is cleaning out the cyclone before it gets too full. In this situation, you could see larger chips get pulled into the collector’s filter. Work Safe!

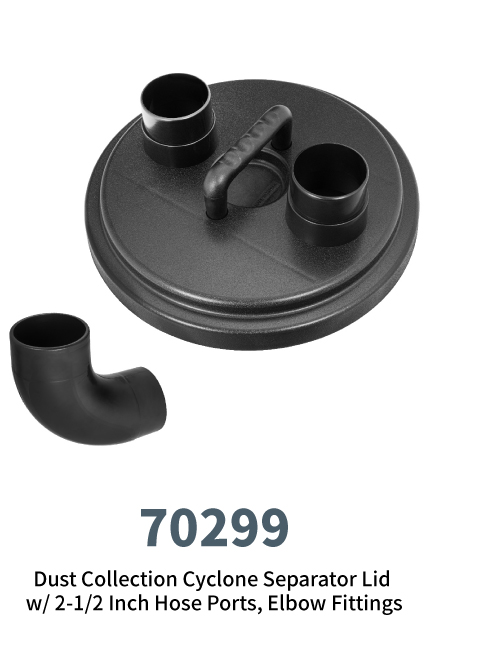

At POWERTEC, we have 4 types of cyclone kits to choose from, depending on how “DIY” you want this project to be - without a doubt, build it yourself. POWERTEC’s four kits range from “everything”, which includes a bucket on casters and everything else you’ll need…to the most basic of kits, elbows and couplers, leaving much of the design up to you.