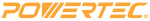

ID vs. OD: What You Need to Know

POWERTEC on May 28th 2025

When it comes to hoses and pipes, you'll see two main measurements: Inner Diameter (ID) and Outer Diameter (OD). For dust collection hoses, ID is the standard because it directly relates to airflow capacity and fitting over tool ports. OD is typically used for PVC pipes and fittings, especially in plumbing-based setups. Knowing which measurement applies to each component ensures compatibility across hoses, pipes, and connectors, making setup easier and your system more efficient.

Tip: Always check product listings and measure your components before ordering to ensure compatibility with your system.

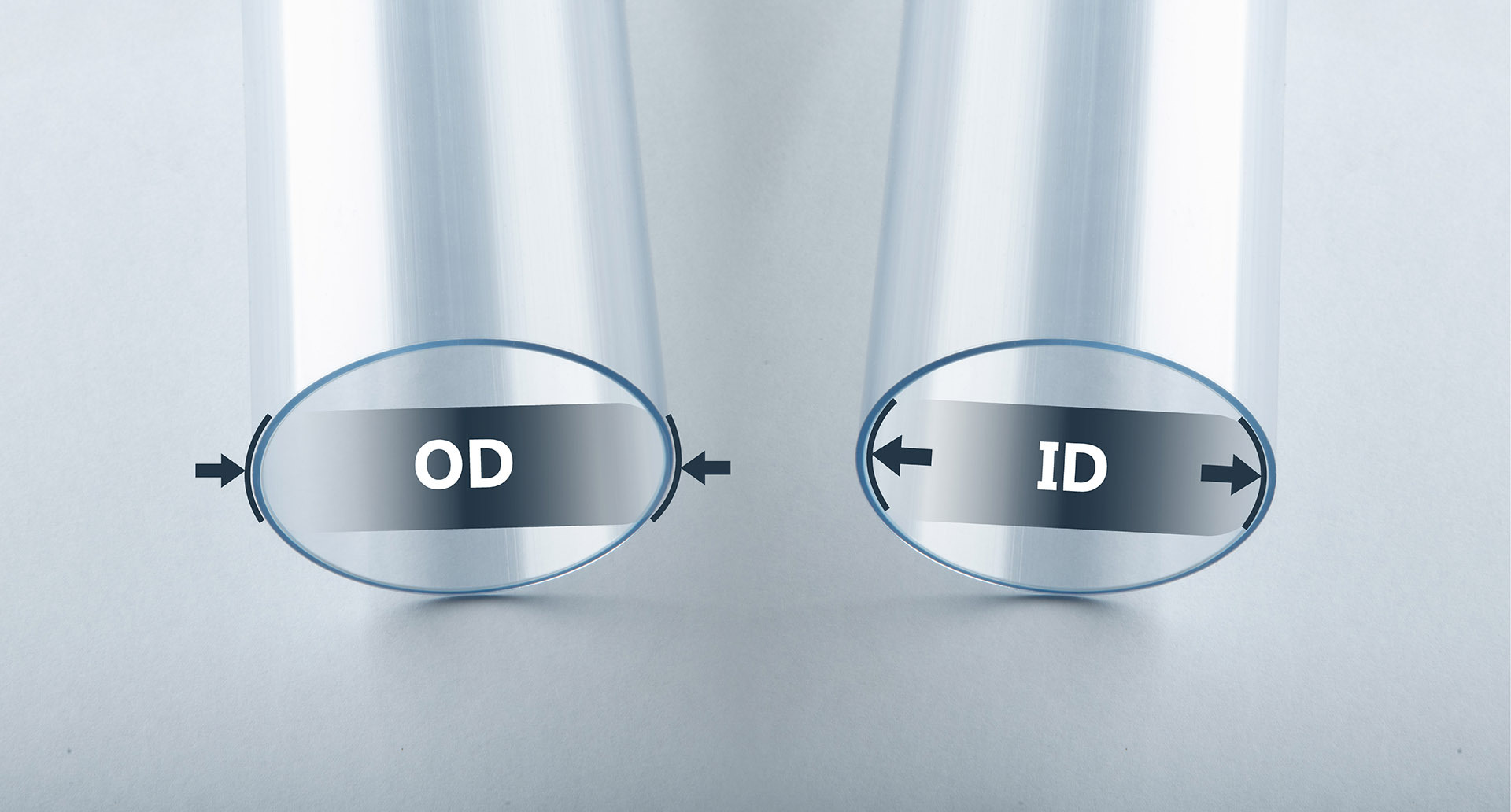

Common Sizes and Uses

In dust collection, certain hose and pipe sizes are standard and generally suit specific tools and setups.

4-inch hoses: Most popular choice for stationary woodworking tools like table saws and planers, providing solid airflow for effective dust removal.

2.5-inch hoses: Common for smaller, portable tools and shop vacuums, where a compact size is preferred.

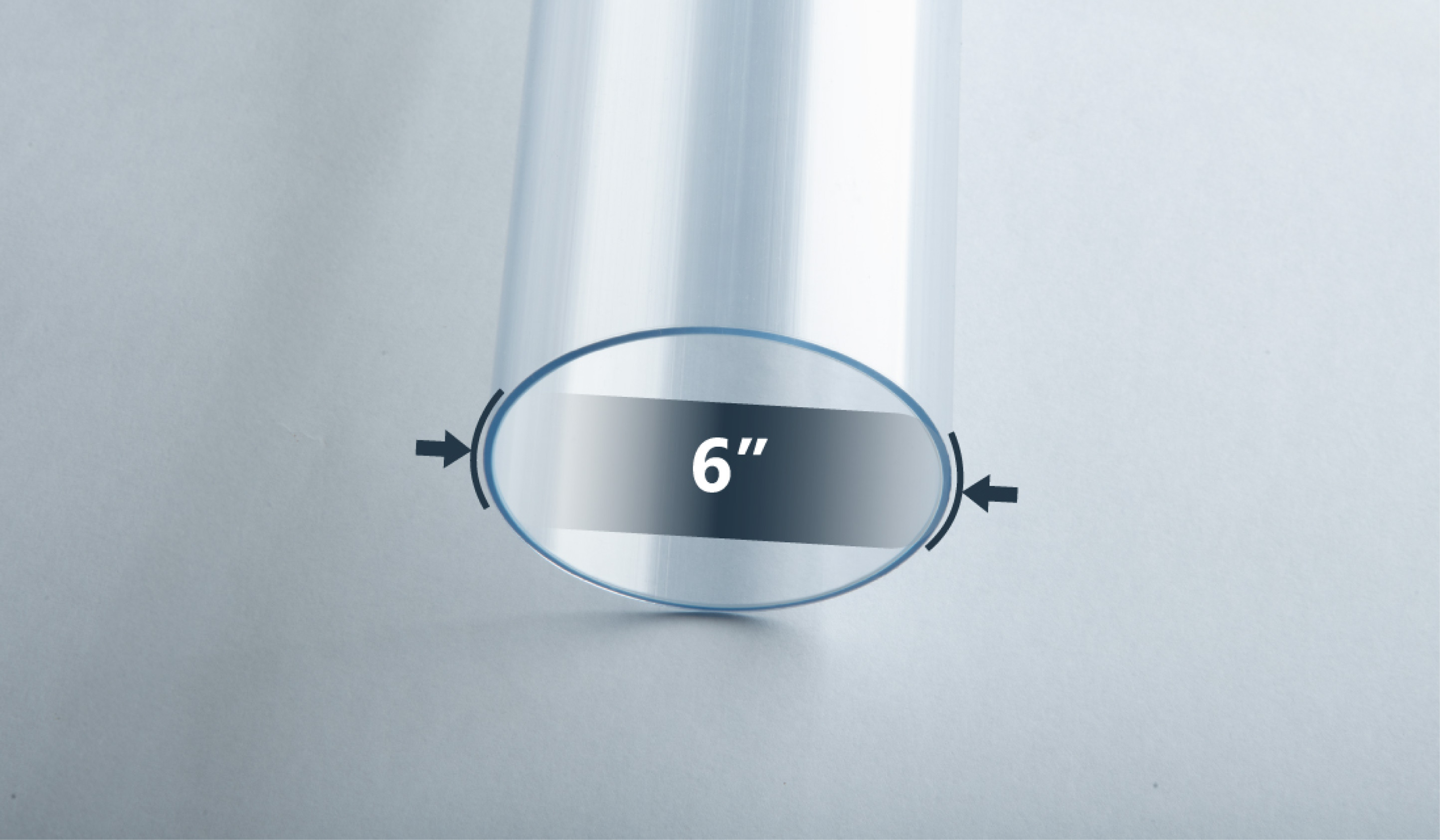

6-inch pipes: Ideal as main lines for larger setups, especially in central systems or profes-sional workshops, handling high dust volumes and supporting multiple tools with steady airflow.

Note: Most fittings are tapered. To get an accurate OD measurement, measure from the top of the opening rather than the bottom.

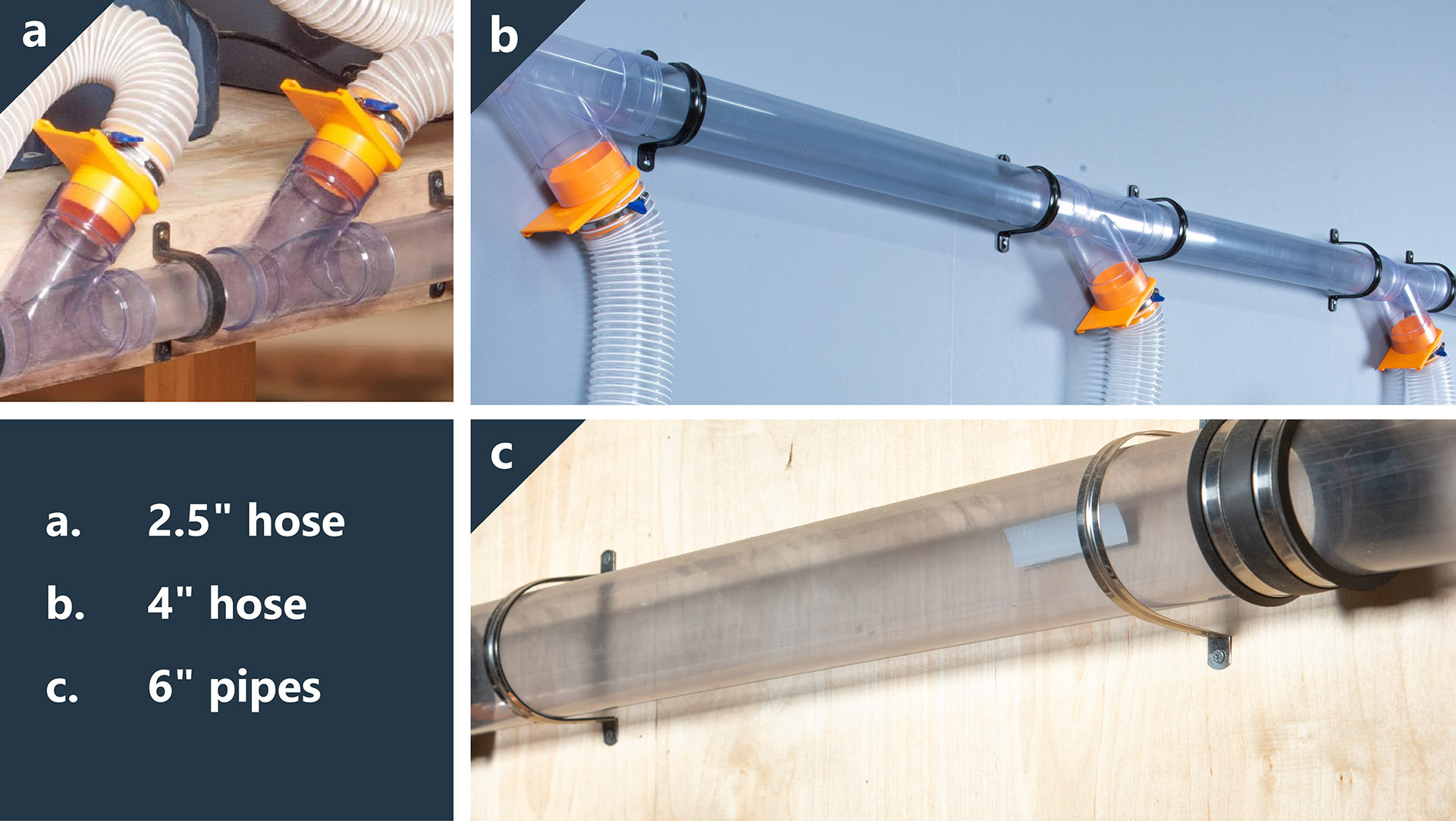

Connectors and Fittings

Connectors and fittings link different pipes and hoses, allowing for custom setups.

Common types include:

Couplers: For joining hoses of the same diameter, such as extending reach or linking hoses without changing the diameter.

Y-Fittings: Used for branching a main line to multiple tools. For example, a 4-inch Y-fitting splits a single 4-inch main hose into two 4-inch branches, each leading to different tools for dust removal.

Reducers: For connecting hoses of different sizes, such as connecting a 6-inch main line to a 4-inch branch.

POWERTEC offers a range of specially sized fittings that may suit your applications. Exam-ples include ID fittings (70320, 70321)* and quick-change styles (70291, 70284, 70285)*. Using our catalog can help you find these options easily.

Creative Use Tip: If you need to connect a 1-1/4" port to a 2-1/2" hose, the inside of a 2-1/2" to 1-1/2" reducer (70138) can serve as a useful adapter.

POWERTEC ID Fittings

70320: A specialized ID-to-ID connector designed for joining two hoses or pipes with identical inner diameters. Ideal for setups where seamless airflow and precision are required.

70321: An ID fitting that accommodates slightly varying inner diameters, providing flexi-bility when working with tools or hoses of similar but not identical sizes. Perfect for custom or unconventional connections.

POWERTEC Quick-Change Fittings

70291: A quick-change tool port designed for fast attachment and removal of hoses to stationary power tools. Its durable, high-impact design ensures a secure fit and minimizes air leaks, making it a versatile addition to any dust collection system.

70284: A quick-change adapter with a tapered design that ensures compatibility with multiple tool port sizes. Great for transitioning between different tools efficiently.

70285: A multi-purpose quick-change connector built to fit a range of dust collection hoses and tool ports. Its universal design offers exceptional versatility and ease of use for work-shops with varied equipment.

Catalog Note: For more details, including precise dimensions and compatibility charts, explore POWERTEC's full product catalog, available online or in print.

Quick Tips for Setup and Compatibility

When joining hoses and pipes, use flexible adapters to help match diameters and secure with hose clamps to prevent leaks. Avoid mixing too many sizes in a single line, as this can reduce suction power. For consistent airflow, keep the main lines as direct as possible, using connectors sparingly.

If a fitting feels too loose due to tolerance differences, masking tape can be wrapped around the OD port to snug the fit.

Sizing Your Dust Collection System

Optimize Airflow in Your Workshop with the Right Pipes, Hoses, and Fittings

1. Introduction: Dust Collection System Basics A properly designed dust collection system is essential for keeping your woodworking workspace clean, safe, and efficient. Choosing the right pipe sizes and connectors isn't just about fitting components together; it directly impacts airflow and efficiency. This guide will help you understand how to size and set up a dust collection system that minimizes clog-ging and suction loss while keeping your tools running smoothly.

2. What's the Difference Between ID and OD in Dust Collection?

Dust collection systems rely on two key measurements: Inner Diameter (ID) and Outer Diameter (OD).

ID: Used for hoses because it directly relates to airflow capacity and fitting over tool ports.

OD: Commonly used for PVC pipes and fittings, especially in plumbing-based setups. Knowing which measurement applies to each component ensures compatibility across hoses, pipes, and connectors, making setup easier and more efficient.

Pro Tip: Always check product listings and measure your components before ordering to ensure they'll fit your system.

3. Common Hose and Pipe Sizes for Dust Collection

Choosing the right hose or pipe size is crucial for optimizing airflow and reducing dust buildup. Here’s how common sizes are typically used in woodworking shops:

4-inch hoses: Perfect for stationary tools like table saws, planers, and jointers. These hoses provide solid airflow for effective dust removal.

2.5-inch hoses: A go-to option for smaller, portable tools and shop vacuums, where a compact size is essential.

6-inch pipes: Best suited as main lines for central dust collection systems in professional workshops. They handle high dust volumes and support multiple tools simultaneously.

Important: Most dust collection fittings are tapered. Always measure OD from the top of the opening for accuracy.

4. Essential Connectors and Fittings for Dust Collection Systems Connectors and fittings are the building blocks of any dust collection system, linking hoses and pipes to create custom setups:

Couplers: Join hoses of the same diameter, extending reach or linking hoses without changing the size.

Y-Fittings: Branch a main line into multiple tool connections. For example, a 4-inch Y-fitting splits a single main hose into two branches, improving dust removal from different tools.

Reducers: Connect hoses of different sizes. For instance, you might connect a 6-inch main line to a 4-inch branch for a specific tool.

Creative Use Tip: Need to connect a 1-1/4” port to a 2-1/2” hose? Use the inside of a 2-1/2” to 1-1/2” reducer (70138) for a perfect fit.

5. POWERTEC Fittings for Dust Collection Systems

POWERTEC specializes in innovative fittings that make dust collection systems more versatile and efficient:

70320: ID-to-ID connector designed for joining hoses or pipes with identical inner diameters. Ensures seamless airflow for precise fits in workshop setups.

70321: Flexible ID fitting that accommodates slightly varying inner diameters. Ideal for custom or unconventional setups.

70291: Quick-change tool port for secure, leak-free connections with stationary tools.

70284: Tapered adapter compatible with multiple tool port sizes for fast transitions.

70285: Universal connector that fits a range of hoses and tool ports, perfect for workshops with frequent setup changes.

Find Your Match: Explore the POWERTEC catalog for detailed specs and compatibility charts to find the ideal fittings for your setup.

6. Quick Tips for Dust Collection System Setup

To ensure your dust collection system operates efficiently, focus on secure connections and consistent airflow. Flexible adapters can help match diameters when joining hoses and pipes, and hose clamps are essential to prevent air leaks. Mixing too many hose sizes in a single line should be avoided, as it can significantly reduce suction power. Keep the main lines as direct as possible to maintain airflow and minimize resistance. If a fitting feels loose, you can wrap masking tape around the OD port to snug the fit and eliminate leaks.