Product Description

Take the Guesswork Out of Precision Setup and Surface Checks

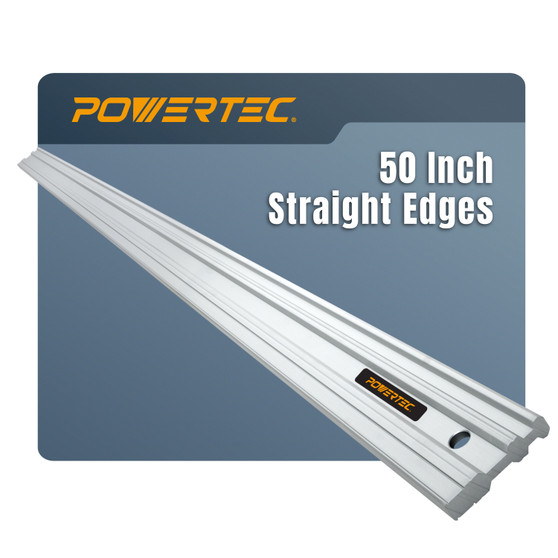

When you're tuning a jointer, checking table saw flatness, or verifying an engine block surface, "eyeballing it" isn't good enough—and a warped yardstick definitely isn't. The POWERTEC 50 Inch Aluminum Straight Edge delivers machine-shop accuracy with a strict .003" tolerance across the full 50-inch length, giving you the confidence to trust your measurements and setups. Machined from solid anodized aluminum with true parallel edges, this one-piece tool eliminates the flex, gaps, and inconsistencies that plague cheaper alternatives. Whether you're a woodworker dialing in machinery, a machinist checking surface flatness, or an automotive tech inspecting cylinder heads, you get reliable reference accuracy that doesn't lie.

What sets this straight edge apart is the hands-free design—at 5/16" thick, it stands upright on its own, freeing both hands for adjustments, feeler gauges, or scribing work. The ribbed reinforcement adds structural stability without excessive weight, while the anodized finish resists wear, corrosion, and the daily abuse of shop environments. Use it to check jointer and planer tables, verify table saw wings, scribe cut lines on sheet metal, align machinery, check engine block decks, or validate any critical surface that demands precision. From cabinet shops to machine shops to home garages, this straight edge delivers professional-grade accuracy at a tool price, not a gauge price.

Key Features & Benefits

.003" Tolerance for True Precision Measurements

- Machined to .003" tolerance across the entire 50-inch span—far more accurate than standard rulers or carpenter's squares, giving you confidence in critical measurements and setup work

- True parallel milled edges maintain consistency for scribing layout lines, checking alignment, or verifying that surfaces are actually flat rather than just appearing straight

- One-piece construction eliminates flex and gaps that multi-section rulers create, ensuring your reference stays accurate even when checking long table saw surfaces or jointer beds

Stands Upright for Hands-Free Operation

- 5/16" thick profile stands on edge without support, freeing both hands to adjust machine components, use feeler gauges, or make marks—no more awkward two-handed balancing acts

- Allows precise gap checking with shim stock or feeler gauges when dialing in jointer tables, planer beds, or verifying table saw flatness without needing a helper

- Makes solo setup work practical and efficient instead of frustrating, especially on larger machines where holding a straight edge steady while adjusting is nearly impossible alone

50-Inch Length Covers Large Surfaces in One Pass

- Spans full-size table saw surfaces, jointer beds, and planer tables without needing to reposition multiple times or question whether your measurements actually line up

- Checks engine block decks and cylinder heads end-to-end for automotive and small engine rebuilds where flatness determines whether gaskets seal properly or blow out

- Long enough for most shop machinery and workbenches while still being manageable to store and handle—not too short to be useful, not so long it becomes unwieldy

Durable Anodized Aluminum Construction

- Anodized finish resists wear, corrosion, and scratching from daily shop use, maintaining accuracy even after years of contact with metal surfaces, moisture, and handling

- Lightweight aluminum makes handling easy without sacrificing the rigidity needed for accurate measurements—much easier to maneuver than steel straight edges of similar length

- Ribbed reinforcement prevents flexing under its own weight when spanning gaps or checking long surfaces, ensuring the tool itself doesn't introduce errors into your measurements

- Built-in hanging hole provides convenient storage so the straight edge stays protected and accessible rather than getting buried under clutter or leaned in a corner where it can be damaged

Versatile Tool for Multiple Precision Tasks

- Check table saw wing alignment and flatness to eliminate snipe, tearout, and feeding problems caused by tables that aren't coplanar with the blade

- Tune jointer and planer tables for perfect face joints by verifying infeed, outfeed, and bed surfaces are truly flat and aligned correctly

- Verify engine block and cylinder head flatness during automotive rebuilds to prevent gasket failure, compression loss, and coolant leaks from warped surfaces

- Scribe accurate layout lines on sheet metal, panels, or long stock where precision matters more than the rough marks from a carpenter's pencil and eyeball

- Check machine bed ways, mill tables, and surface plates in machining or fabrication environments where surface accuracy directly impacts finished part quality

WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.gov