Planer vs Jointer — What’s the Difference & Which Comes First?

POWERTEC on Nov 27th 2025

The Secret to Perfectly Flat, Smooth Boards

Precision starts long before the first joint or finish coat. It begins with how flat and even your lumber is. Two tools often mentioned together—the planer and the jointer—are the key to building that smooth, square foundation every great project needs.

Core question: What’s the difference between a planer and a jointer—and which should you use first?

What Does a Jointer Do?

A jointer is your first step toward flat, true boards. It removes warps, twists, and cups from rough lumber—giving you one perfectly flat face and one square edge.

- Flatten warped/uneven lumber to create a reference face

- Square an edge for glue-ups and joinery

- Prep stock for the planer

Recommended Tool: POWERTEC PRO 6-Inch Benchtop Jointer (BJ603)

- Precision Power: 10-amp motor, up to 22,000 cuts/min; removes up to 1/8" per pass

- Accuracy & Control: 30" × 6-1/4" table, adjustable fence 90°–135°, T-slots for accessories

- Dust Management: 2-1/2" dust port integrates with POWERTEC dust collection

What Does a Planer Do?

After one face is flattened on the jointer, the planer makes the opposite face parallel and brings the board to final thickness—leaving both faces smooth.

- Uniform thickness across boards

- Smooths rough-sawn lumber

- Creates parallel faces for precise joinery

Recommended Tool: POWERTEC PRO 15-Amp 13-Inch 3-Blade Benchtop Planer (PL1303)

- Powerful Performance: 2 HP motor, 9,400 RPM cutterhead, 28,400 cuts/min; handles up to 6" × 13"

- Precision & Control: lead-screw height system, depth stop, easy-to-read gauge

- Cleaner Workspace: transparent 4" dust port; pair with POWERTEC 70365 90° Elbow to keep hose clear of the outfeed zone

- Built to Last: 3-blade cutterhead with reversible HSS knives for blemish-free finishes

The Key Difference Between a Planer and a Jointer

| Feature | Jointer | Planer |

|---|---|---|

| Primary Function | Flattens one face & squares an edge | Makes opposite face parallel; sets thickness |

| When to Use | First | After jointing |

| Result | Flat reference surface | Uniform thickness & smooth finish |

| Common Mistake | Trying to flatten twisted boards | Trying to square rough edges |

Simple Rule: A jointer makes the board flat and square. A planer makes it uniform and smooth. Together they turn rough lumber into precision-milled stock.

Which Comes First: Planer or Jointer?

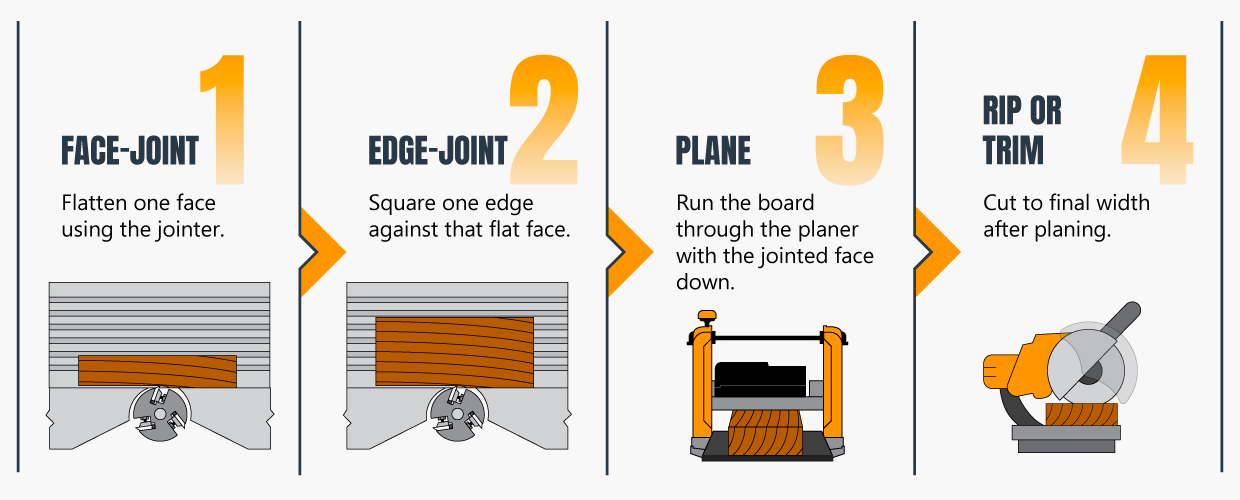

Pro Tip: After flattening one side on your jointer, mark it with chalk. That’s your reference face in the planer.

Do You Need Both a Planer and a Jointer?

Yes—if you want furniture-grade precision.

- A planer alone can’t flatten a warped board.

- A jointer alone can’t create consistent thickness.

For small workshops, benchtop models like the PL1303 and BJ603 deliver the ideal blend of power, precision, and compact size.

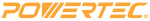

How Planers and Jointers Work Together

- 1. Flatten one face (jointer)

- 2. Square one edge (jointer)

- 3. Plane to final thickness (planer)

- 4. Cut to width and length (table saw / miter saw)

When to Upgrade or Replace Blades

Sharp knives are essential for safe, clean cuts. If you notice tear-out, chatter, or burn marks, it may be time to flip or replace your blades. POWERTEC offers reversible HSS sets for planers and jointers—including models compatible with DeWalt, Ridgid, and Delta.

Final Takeaway: Flat Starts Here

The jointer gives you one true face and square edge. The planer makes the opposite side smooth and parallel. Together, they transform rough lumber into perfection-ready stock. Investing in quality machines like the POWERTEC Planer PL1303 and BJ603 means your projects start—and finish—flat, square, and flawless.

FAQs About Planers and Jointers

Q: What’s the difference between a planer and a jointer?

A: A jointer flattens and squares lumber; a planer makes it uniformly thick and smooth.

Q: Which comes first: jointer or planer?

A: Always use the jointer first to create a flat reference surface, then use the planer to make the opposite face parallel.

Q: Do I need both a planer and a jointer?

A: Yes. A planer can’t flatten twisted wood, and a jointer can’t ensure consistent thickness—they work best as a team.