Matching Blade Materials to Your Cutting Needs

POWERTEC on Sep 1st 2025

|

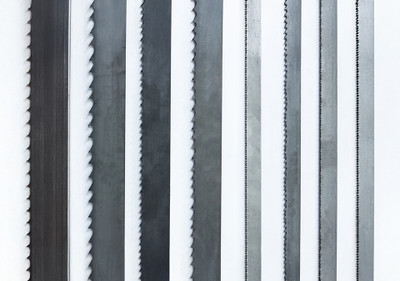

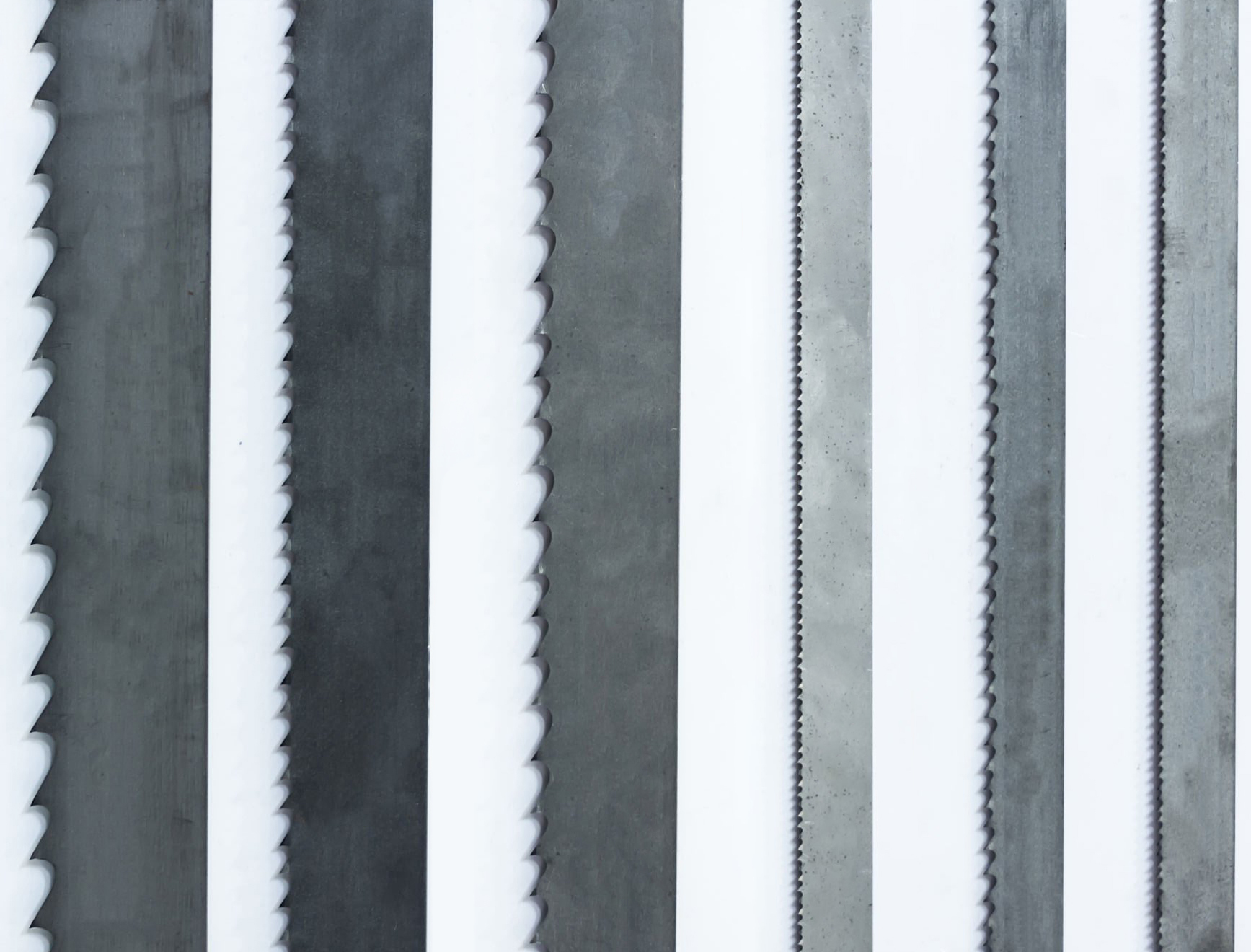

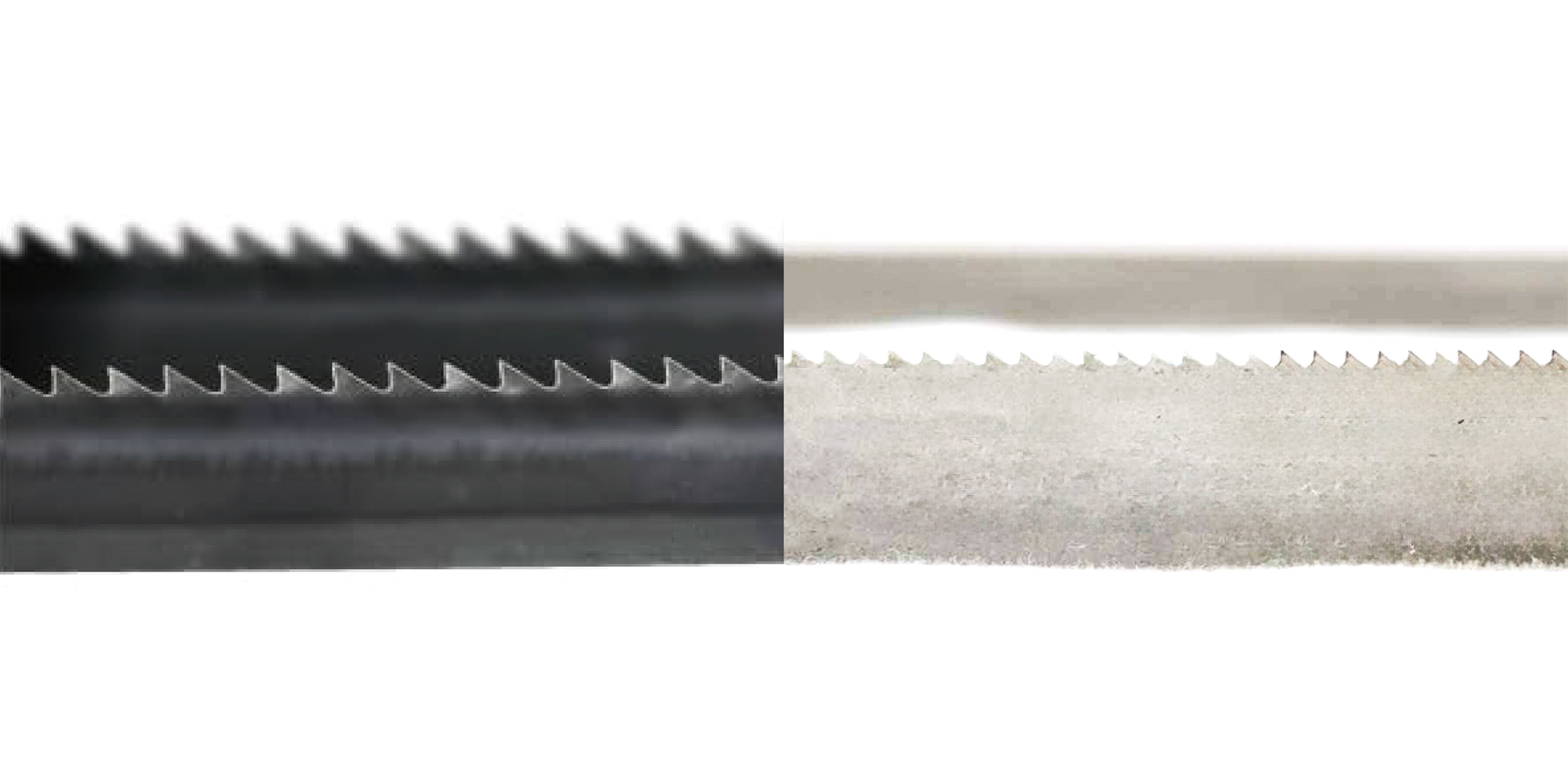

The material of your bandsaw blade is just as important as its length, width, and TPI. Different blade materials are designed to handle specific tasks, and selecting the right one ensures precision, efficiency, and longevity. The two most common types of band saw blade materials are carbon steel and bi-metal, each offering distinct advantages based on your cutting requirements. Understanding these options can save you time, money, and frustration. |

| Carbon steel blades are the go-to choice for woodworking and light-duty applications. They are affordable, flexible, and capable of clean cuts in softwoods, hardwoods, and plastics. If your projects primarily involve woodworking or occasional cuts in non-abrasive materials, carbon steel is a practical, cost-effective option. However, these blades have limitations—they wear out faster when cutting dense or abrasive materials like MDF or composites, making them better suited for short-term, low-stress projects. |

|

|

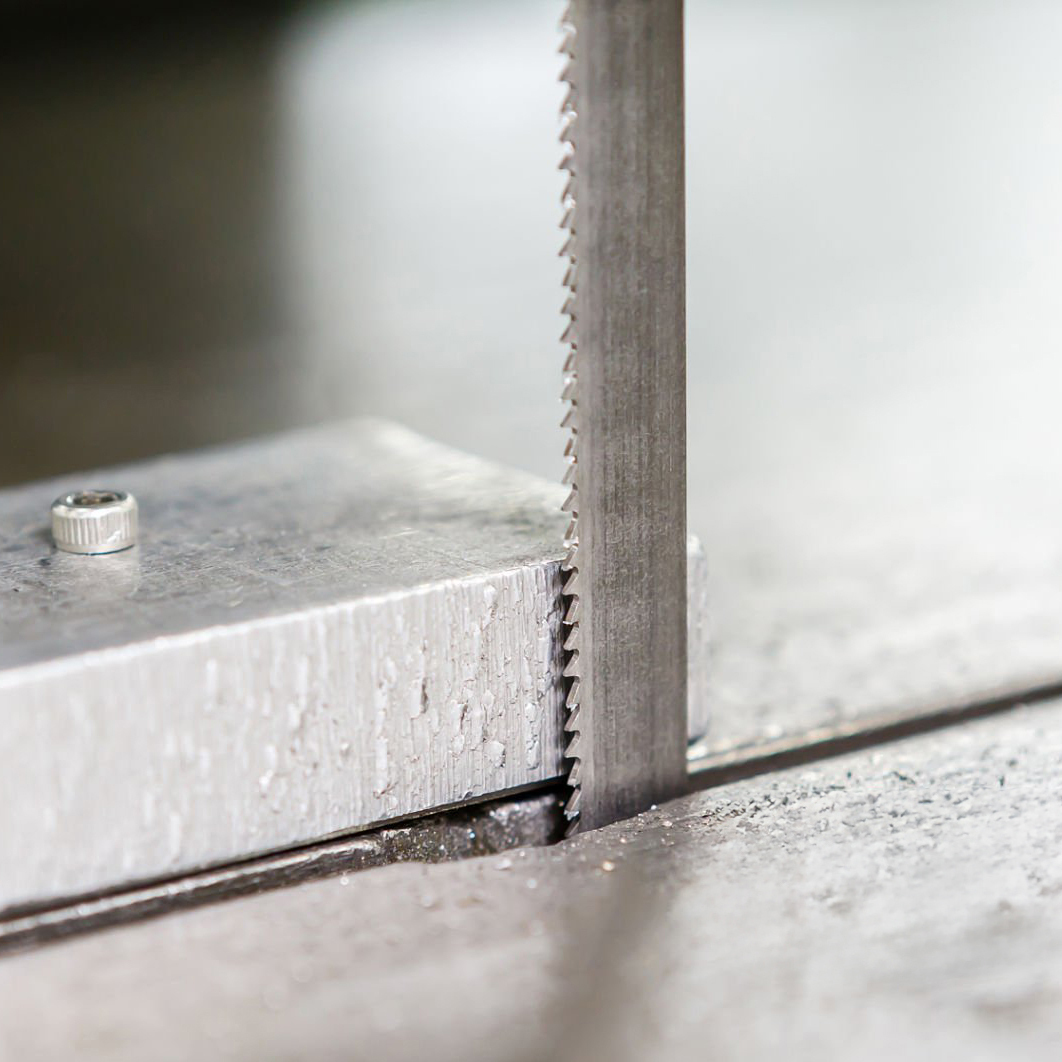

For more demanding tasks, bi-metal blades offer superior durability and versatility. These blades are constructed with a high-speed steel cutting edge bonded to a flexible alloy steel backing. This dual-layer construction gives them the ability to handle tough materials like stainless steel, thick hardwoods, and dense composites. Bi-metal blades excel in mixed-material projects, eliminating the need to switch blades frequently. While they have a higher upfront cost than carbon steel blades, their extended lifespan and reliability make them a worthwhile investment for professionals and heavy-duty users. |

If your work involves cutting metals regularly, bi-metal is the clear choice. These blades resist heat buildup, maintain their sharpness longer, and are less prone to cracking under high stress. Additionally, bi-metal blades can handle both ferrous and non-ferrous metals, making them an excellent all-around option for fabrication shops or workshops where versatility is key. For projects requiring precision and efficiency across multiple materials, bi-metal blades deliver consistent, high-quality results.

POWERTEC offers a range of blade materials to suit every need. From flexible carbon steel for woodworking to robust bi-metal blades for heavy-duty cutting, our selection ensures you’ll find the perfect match for your project. Choosing the right blade material is more than a technical decision—it’s about optimizing performance and achieving the best results. The wrong blade material can lead to uneven cuts, premature wear, or even equipment damage. By selecting a blade material tailored to your specific tasks, you can enhance both your productivity and the lifespan of your band saw. Explore POWERTEC’s comprehensive range of high-quality blades and take the guesswork out of your next project.

|

|

| Blade Material | Best Uses | Advantages | Limitations |

| Carbon Steel | Woodworking, softwoods, hardwoods, plastics | Affordable, flexible, clean cuts | Wears out quickly on dense or abrasive materials |

| Bi-Metal | Mixed materials, metals, dense hardwoods, composites | Durable, heat-resistant, long-lasting | Higher upfront cost |