Circular Saw Blades 101: How to Choose the Right Blade

POWERTEC on Oct 17th 2025

The Difference Between a Clean Cut and a Rough Edge? Your Blade.

A clean cut starts long before you pull the trigger; it all starts with your circular saw blade. Choosing the right one can mean the difference between a buttery-smooth finish and a splintered edge that ruins your project.

If your cuts burn, chip, or wander off-line, chances are the blade isn’t matched to the job. Here’s your quick-cut guide to understanding sizes, teeth, and kerf so you can cut cleaner, faster, and safer every time.

1. Why Your Circular Saw Blade Choice Matters

A circular saw is only as good as its blade. The wrong blade can slow your saw, overheat the motor, and tear through material instead of slicing it. The right one glides through wood, keeps your saw cool, and leaves edges you’re proud to show off.

Pro Tip: Don’t rely on the stock blade that came with your saw. It’s designed to sell the tool, not to serve your work.

2. Know Your Blade Basics

Blade Diameter and Arbor Size

Your first compatibility check.

- Most cordless saws: 6-1/2 inches

- Standard circular saws: 7-1/4 inches

- Table/miter saws: 10 inches or more

Most handheld saws use a 5/8-inch arbor. Always match diameter and arbor; mismatches can be unsafe.

Tooth Count and Cut Finish

When it comes to choosing a circular saw blade, the number of teeth directly affects both the speed and the quality of your cut. Fewer teeth make quick work of rough lumber, while higher tooth counts deliver smooth, precise finishes on sheet goods and trim. Here’s how to match tooth count to your project:

| Tooth Count | Best For | Result |

|---|---|---|

| 24 T | Fast rips & framing | Quick, powerful cuts through construction lumber and softwood. |

| 40 T | General-purpose DIY & remodeling | Balanced speed and finish for everyday cuts in plywood, MDF, or hardwood. |

| 60–80 T | Plywood, trim & fine woodworking | Smooth, clean cuts with minimal tear-out—perfect for cabinets or furniture building. |

Pro Tip: If you’re building up your toolkit, start with a 24T blade for framing, a 40T combination blade for general cuts, and a 60T–80T finish blade for detail work. That trio covers nearly every woodworking scenario—from rough cuts to precision finish work.

Tooth Materials: What Your Blade Is Made Of

Most circular saw blades today use carbide-tipped teeth, which stay sharper far longer than plain steel and cut both wood and composites cleanly. You’ll also find high-speed steel (HSS) blades, which are affordable but better suited to light, occasional cuts, and diamond-tipped blades for masonry, tile, and other hard materials.

Quick Tip: Choose carbide-tipped blades for everyday woodworking; they deliver the best balance of sharpness, durability, and value.

Kerf Width: Thin vs Full

The kerf is the width of material the blade removes.

- Thin Kerf (< 1/8”): less resistance, ideal for cordless saws.

- Full Kerf (≈ 1/8”): more stability on high-power tools and thicker stock.

Modern Blade Features That Make a Difference

Many newer blades include non-stick coatings, laser-cut expansion slots, and anti-vibration vents. These details help the blade run cooler, reduce noise, and prevent warping under heavy use—so every cut stays straight and smooth.

3. Match the Blade to Your Material

The best circular saw blade depends on what you’re cutting and how clean you want the finish to be. Different materials respond better to specific tooth designs, grinds, and counts. Here’s a quick guide to help you match your project with the right blade setup:

| Material | Recommended Blade | Result |

|---|---|---|

| Framing Lumber | 24 T Flat-Top Grind (FTG) | Fast, efficient rips through softwood and framing stock. |

| Plywood / MDF | 40–60 T Alternate Top Bevel (ATB) | Smooth, splinter-free cuts on sheet goods and engineered wood. |

| Trim / Finish Work | 60–80 T Low-Hook ATB | Polished edges with no tear-out—ideal for molding, cabinetry, and detail work. |

Quick Rule: Fewer teeth = faster cut. More teeth = finer finish.

4. Power, Hook Angle & Feed Control

You don’t need to be an engineer to understand hook angle:

- Positive hook (teeth lean forward) → grabs aggressively, ideal for ripping.

- Neutral/Negative hook → gentler feed, safer for miter saws & finish cuts.

Think of it as “how eager your blade is to bite.”

5. Quick Checklist Before You Buy

- 1. Confirm blade diameter & arbor fit.

- 2. Pick tooth count for your material.

- 3. Choose thin kerf for cordless, full kerf for high power.

- 4. Look for carbide-tipped teeth and anti-vibration slots.

- 5. Stick with trusted brands for consistent, accurate cuts.

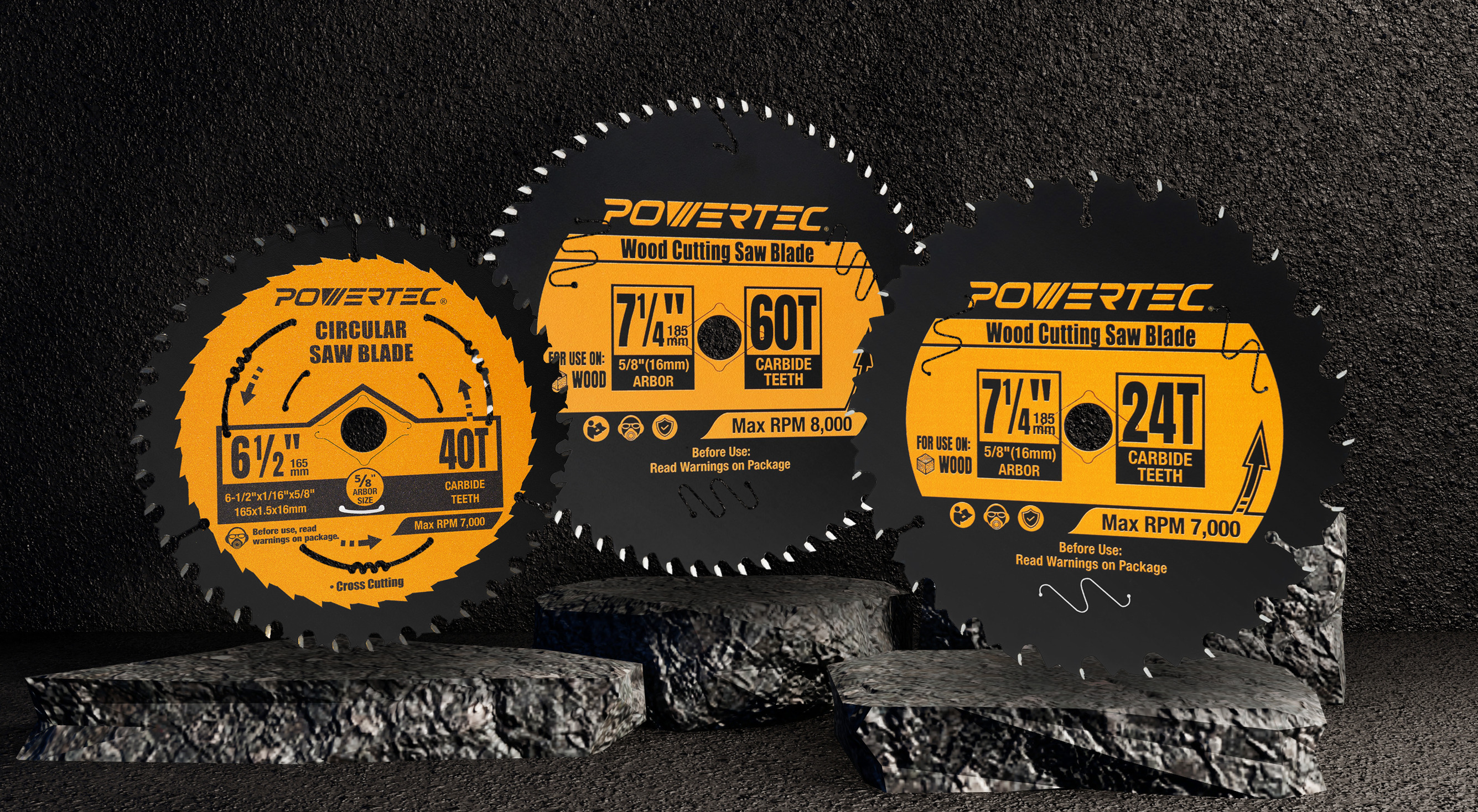

Recommended POWERTEC Blades

To make it easier to choose the right circular saw blade for your next project, here are a few trusted options from the POWERTEC lineup. Each one is built with carbide-tipped teeth for durability, smoother cuts, and long-lasting precision.

| Blade | Best For | Details |

|---|---|---|

| 7-1/4″ 24 T Carbide Blade (14015) | Ripping & Framing | Designed for fast, aggressive cuts through softwood and construction lumber. Ideal for framing and rough carpentry. View Blade › |

| 6-1/2″ 40 T General Purpose Blade (14023) | Everyday DIY Projects | A balanced, all-around performer that handles plywood, MDF, and hardwood with a smooth finish. Great for remodeling and general woodworking. View Blade › |

| 7-1/4″ 60 T Finish Blade (14016) | Plywood & Fine Cuts | Made for clean, splinter-free edges on sheet goods, trim, and cabinetry. Perfect for fine woodworking and furniture making. View Blade › |

FAQs About Circular Saw Blades

Q: How many teeth should a blade have for plywood?

A: Choose a 40–60 T ATB blade for smooth, chip-free cuts.

Q: What’s the difference between thin and full kerf?

A: Thin-kerf blades cut faster and draw less power; full-kerf blades stay stiffer under heavy load.

Q: Can one blade do everything?

A: A 40 T combination blade can handle most DIY tasks, but specialty blades deliver better results for specific materials.