Miter Gauges and Sleds: Cutting Angles, not Corners

POWERTEC on Jan 20th 2021

Adding a miter gauge or sled to your table saw opens it up many new uses, turning it into a more rounded tool than one primarily for ripping – now you can crosscut too, and with accuracy. For many woodworkers, these affordable add-ons can even take the place of a miter saw, saving $500 or more on a tool that may spend most of its life gathering dust on a shelf.

Why Get a Miter Gauge or Sled?

To make crosscuts and angled cuts accurately, it’s that simple. To make cuts and have the ability to repeat those cuts exactly, piece after piece, again and again. You might be thinking “But my table saw already has a built-in miter gauge!” Truthfully, there’s a 99% probability that the built-in gauge isn’t accurate enough to cut gap-free, tight-fitting joints. After-market gauges usually include adjustable miter bars and fences that increase both accuracy and safety, when compared to OEM miter gauges. When you buy an after-market miter gauge or sled from a reputable manufacturer, what you’re really buying is precision and accuracy.

Sleds vs. Gauges: Both tools effectively do the same thing; however, how they do it and your needs determine which tool you’ll use. In a best-case scenario, you’ll have both at your disposal.

Crosscut Sleds

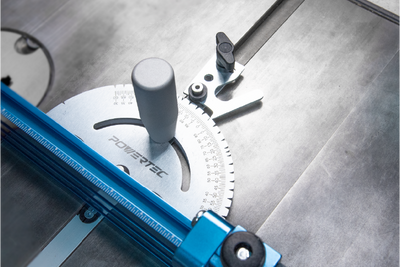

The top two reasons to add a sled to your table saw are angle accuracy and repeatability. If you’re making angled cuts, the large protractors on most name-brand sleds allow you to set the protractor to fractions of degrees with ease. Do you need a 22.5-degree angle? Unless it’s pre-marked on your miter gauge, that octagon picture frame you’re making may have some gaps in the joints. Also, the sled fence, along with an adjustable stop (or clamped-on stop) means that cutting the same angles to the same lengths, repeatedly, can be done with accuracy and with little-to-no set-up time between pieces.

Another reason for using a sled is for shop safety. When cutting on a miter sled, the bottom of the piece does not slide against the table as it sits on the sled and the sled moves. This makes the piece you’re working on much less likely to shift or move as you push it through the blade. This can be a major issue when cutting at angles other than 90 degrees. Another safety issue comes when working on smaller pieces. A miter gauge may leave fingers too exposed to the blade. With a miter sled, smaller pieces can be clamped on to the sled fence and then safely cut.

Miter Gauges

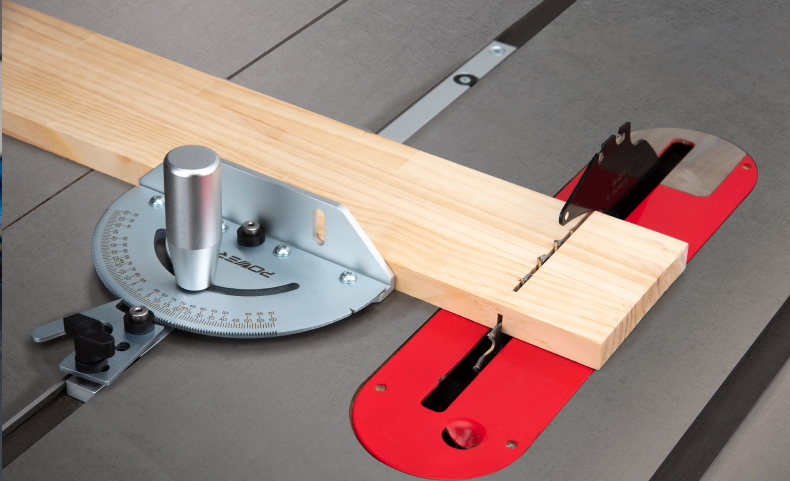

Compared to a miter sled, the top reasons to choose a miter gauge include price and ease of set-up and storage. For quick, angled cross-cuts, a miter gauge is the ideal tool. In some instances, a miter gauge might be a little more versatile than a sled as it can be used with other workshop tools such as bandsaws. However, it’s important to take into account the size of the piece you’re crosscutting. Anything too large or too small (so that it compromises your safety) really should be cut on a sled.

Final Words

In an ideal world, you’ll have both a sled and a miter gauge in your workshop, depending on your needs at the time. Until that day, pick your angle-cutting tool based on your present needs. For large cumbersome pieces, or very small pieces that might place your fingers too near the table-saw blade, a crosscut sled might be your best option. The same goes for repetitive cuts. For occasional usage on manageable pieces that don’t compromise your safety, a miter gauge might be the better option. Good luck with your next project!