A Bit About Bits: POWERTEC Router Bits

POWERTEC on Jan 5th 2022

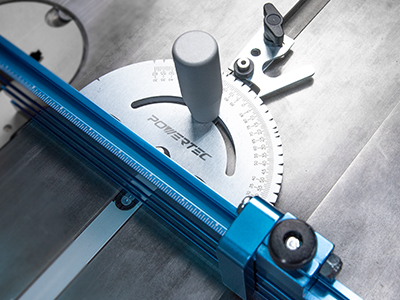

A router is easily the most versatile tool in any home workshop - amazing for something that disassembles into little more than a downward facing motor, a base, and a sharp bit.

How versatile? In any workshop you’ll see routers used to cut grooves, rebates, decorative flutings, profile edges, cut inlays, shape wood, drill holes, recess hinges, cut traditional joints, and cut screw threads. In short, if you don’t have a router already, it should be at the top of your wish list.

The tool’s flexibility comes from the swappable bits used. There’s a lot of choice in the styles, size and bit application; however, there’s so much choice (100s) it might even be confusing. If you’re just starting out, we recommend the following nine

router bits as they cover most common usage.

|

|

|

|

|

Core Box Router BitSKU:73010 This bit cuts round-bottomed grooves and is often used to rout flutes in columns and for making decorative grooves on doors and cabinets. |

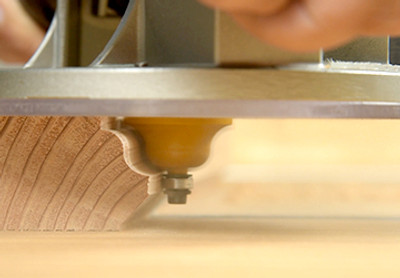

V-Groove BitSKU:73010 Like the core-box, but this cuts V-shaped grooves often seen on cabinet doors, table legs and wall paneling. |

|

|

|

|

|

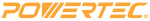

Roman Ogee BitSKU:73010 Another edge-shaping bit, the roman ogee creates a distinctive, classical look. |

Rounding-Over BitSKU:73010 An edge-shaping bit used to round a sharp edge. |

|

|

|

|

|

Flush-Trim BitSKU:73010 Used to trim shelf-edging, veneer or laminates, this bit cuts one surface making it flush with a guiding surface. |

45-Degree Chamfer BitSKU:73010 Cuts a 45-degree angle into the edge of a panel. Make beveled edges for multi-sided projects. It’s also used for decorative edges. |

|

|

|

|

|

Straight Cutting BitsSKU:73010 Use to cut rabbets, dadoes and grooves. |

Dovetail BitSKU:73010 These are used to make sliding dovetail joints. |

Tipped T-Slot BitsSKU:73021-73027

Used to create slots for display walls or to make shop-built jigs and fixtures.

What to look for

These days, high-quality bits come with carbide cutters as they hold their edge much longer than high-speed steel (HSS). They’ll be very sharp to touch and thick enough to allow multiple grindings.

The edges should catch the light (they’re so sharp), and there should be no visible gaps where the edges meet the body of the bit.

Carbide costs more than HSS, but it pays for itself in the long run with life and durability. According to “Router Techniques” carbide blades can last 80 to 90% longer than HSS. Finally, check the bit configuration. Bits with two cutting edges are much better at making smooth cuts.

Good luck on your router projects!

Read Our Other Blog Topics:

|

|

|

|

||

|

|

|

|