Understanding Bandsaw Blade TPI and Cutting Performance

POWERTEC on Jul 28th 2025

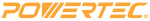

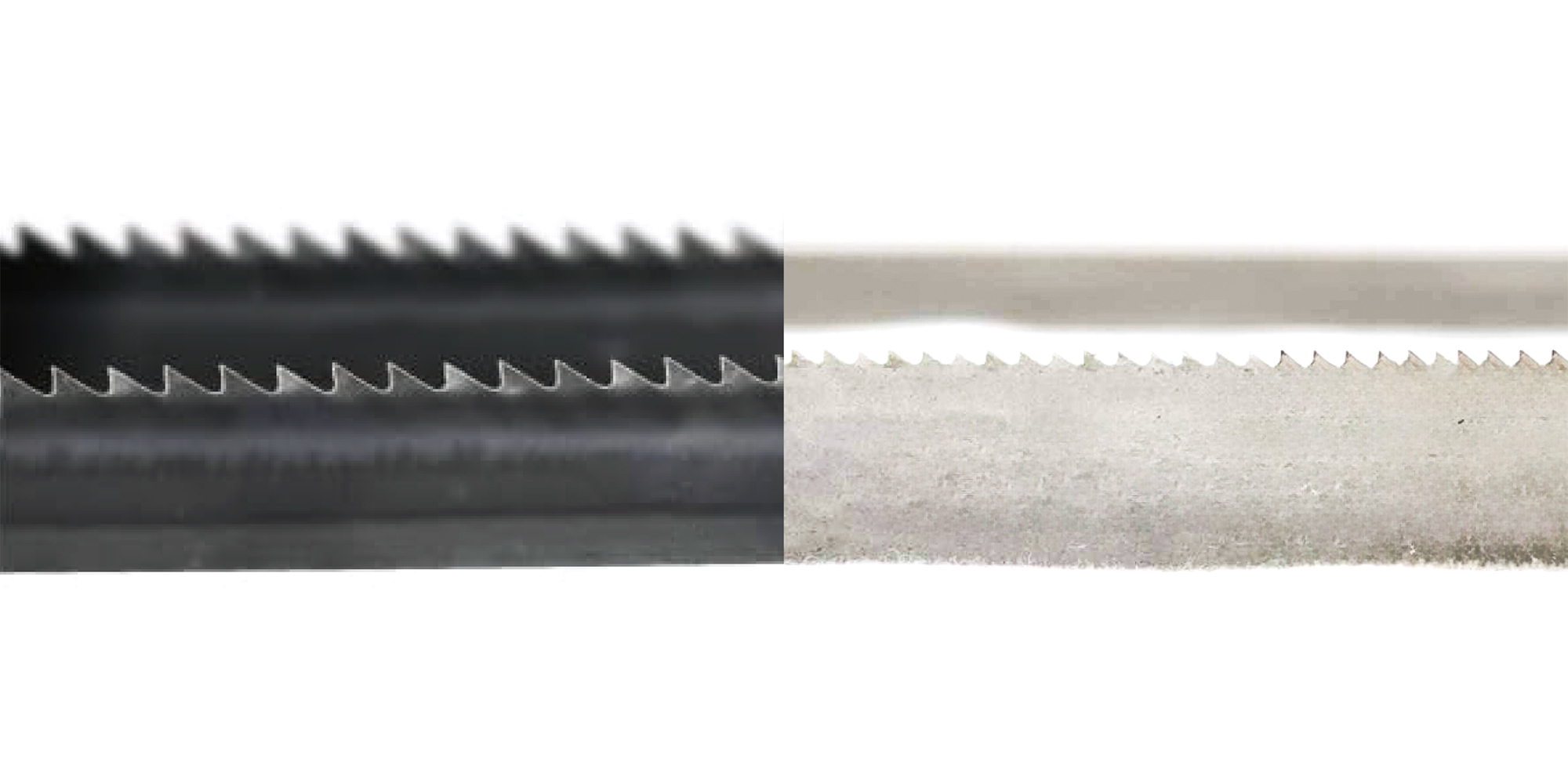

TPI, or teeth per inch, is one of the most critical factors in selecting a band saw blade. It directly affects the speed, smoothness, and quality of your cuts. A blade with a lower TPI—typically 3 to 6—is designed for fast, rough cuts. These blades are ideal for cutting thick materials like hardwoods or logs, where speed and chip clearance are essential. On the other hand, blades with a higher TPI, such as 18 to 24, excel at producing smooth, precise cuts. These are best for thinner materials, such as veneers, plastics, or soft metals, where a clean finish is critical.

Medium TPI blades, ranging from 8 to 14, strike a balance between speed and finish quality. These are the go-to option for general-purpose cutting, handling a wide range of materials efficiently. They’re versatile enough for most projects, whether you’re working with medium-density woods, plastics, or even some metals. The choice of TPI largely depends on the thickness of the material and the level of detail required. Thicker materials benefit from lower TPI, while thinner materials demand higher TPI for smoother cuts.

| Matching TPI to your material and project needs is key to success. For woodworking, a 3–4 TPI blade is excellent for resawing or cutting through thick hardwoods. If you’re working on intricate designs or cutting curves in thinner wood, a blade with 10–14 TPI will deliver finer results. For metalworking, higher TPI blades provide the precision needed for softer metals, while 6–8 TPI blades handle tougher, thicker metals effectively. |  |

Choosing the wrong TPI can lead to problems like rough edges, overheating, or slower cutting speeds. For example, using a blade with too many teeth for a thick material can clog the teeth with debris, causing the blade to overheat or break. Conversely, using a blade with too few teeth on a thin material can result in a jagged finish. By understanding how TPI affects performance, you can ensure cleaner, more efficient cuts.

POWERTEC offers a wide range of TPI options to suit every project. Our low-TPI blades are designed for speed and chip clearance, while medium and high-TPI blades cater to precision and smooth finishes. Whether you’re cutting wood, plastic, or metal, our selection ensures you’ll find the right blade for your needs.

Selecting the proper TPI is more than a technical choice—it’s about improving your workflow. The right blade not only ensures better results but also saves time and extends the life of your equipment. Explore our comprehensive range of bandsaw blades to find the perfect TPI for your next project.

|

|

| Aspect | Key Points |

| TPI Basics |

|

| Blade Durability |

|

| Applications |

|

| Special Considerations |

|

| Recommendations |

|