Selecting Bandsaw Blade Width

POWERTEC on Jul 28th 2025

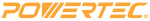

Blade width is a critical factor in determining the precision and type of cuts your bandsaw can achieve.

|

Simply put, the width of the blade—the distance between its back edge and teeth —impacts its flexibility and stability. Narrow blades, typically ranging from 1/8" to 1/4", are perfect for intricate cuts and tight curves. These blades are flexible enough to maneuver smoothly through detailed designs, making them ideal for artistic woodworking, crafting, and projects requiring fine details. |

On the other hand, wider blades, such as those 3/4" and above, excel at straight cuts and resawing tasks. Their increased stability minimizes blade drift, ensuring cleaner, straighter cuts when working with thick materials. Medium-width blades, like those 3/8" to 1/2", strike a balance between flexibility and stability, making them versatile for both straight cuts and mild curves. Selecting the right blade width means assessing the complexity of your project and the type of cuts required.

Choosing a blade width also depends on the material and the saw’s capabilities.

Narrow blades are commonly used for softer materials such as pine or thin plywood, where intricate patterns are required. However, they may struggle with denser woods or composites, as their flexibility can lead to wandering cuts. For heavy-duty projects like resawing hardwood or cutting thick beams, wide blades provide the stability needed to handle the material’s resistance and prevent blade twisting. Your band saw’s wheel size is another important consideration. Smaller saws with compact wheels may only accommodate narrow blades, while larger, industrial saws can handle wider blades for greater cutting power. Always check your band saw’s specifications before selecting a blade width, as using an incompatible blade can cause damage or poor performance.

We offer a range of blade widths to suit every cutting need. From 1/8" blades for precision curves to 3/4" blades for heavy-duty resawing, our selection ensures you’ll find the right tool for your project. Pairing the correct width with your saw and material is key to achieving both efficiency and quality in your cuts. Blade width isn’t just about straight vs. curved cuts—it’s about balancing precision and stability. A narrow blade might navigate the tightest designs, but it won’t stay straight on a thick board. Conversely, a wide blade ensures stability but sacrifices maneuverability.

By understanding these trade-offs, you can confidently choose the blade width that aligns with your project goals.

|

|

| Blade Width | Best Uses | Material Recommendations | Saw Size |

| 1/8" to 1/4" | Intricate curves, tight patterns, freehand cuts | Softwoods, thin plywood, soft plastics | Compack or small band saws |

| 3/8" to 1/2" | General-purpose cuts, moderate curves | Medium-density woods, general plastics | Medium to large band saws |

| 3/4" and above | Straight cuts, resawing, heavy-duty cutting | Hardwoods, thick beams, dense composites | Larger or industrial band saws |