Router Bit Cleaning & Maintenance

POWERTEC on Jan 25th 2022

Router bits are a considerable investment in anyone’s workshop. With time and usage, they will dull, they will wear down, and bearings may fail - it’s inevitable. The good news is, how you care for them will determine how quickly they need to be replaced.

Will they need to be professionally sharpened? Yes. The advice we’re giving here are the steps you can take to prolong the times between having them sent to the shop for a thorough sharpening.

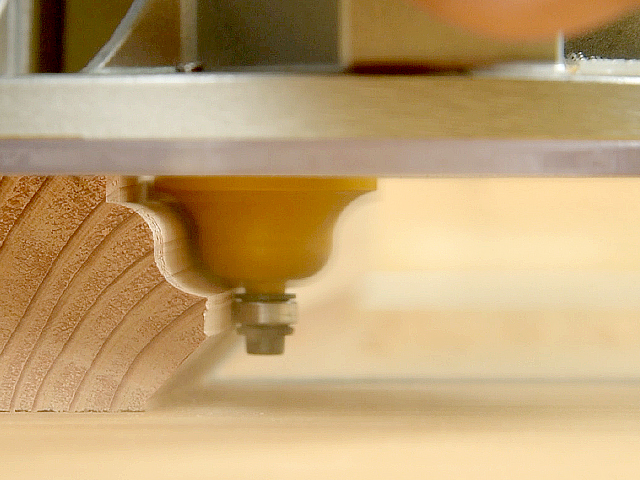

Cleaning your Router Bits

In a perfect world, you’ll clean your router bits every time you use them. The wood pitch, crud, or gunk (whatever you choose to call it), builds up with usage and makes the bit run hotter and become dull. Sometimes this crud can make an otherwise sharp bit seem like it’s dull. The tell-tale signs being rough cutting and burn marks.

We recommend using a commercial “blade and bit” cleaner to remove the crud. Many of these cleaners also double as lubricants which is great for the bearings. Spray on the cleaner and let it sit for a few minutes and then wipe the crud off the bit. Use a large, thickish rag to clean the bit. If you need to remove the bearing first, wrap the bit in a clean cloth and then use an Allen key to snap the nut out.

For deep, baked on crud, let the cleaner sit for a few more minutes and then use a graphite pencil or a copper-wire brush to edge it off. Neither one of these will mark or damage the carbide. If a particularly ‘gunky’ bit you are cleaning has been running dull, once clean, that’s a good time to test the bit. In many cases, the baked-on crud may have been responsible for the rough cuts or burn marks and you can avoid running a diamond sharpener over it.

Maintaining your Router Bits

Before any router bit maintenance, the router bit need to be clean. You’ll also need to remove the bearings. For the actual maintenance, we recommend using a credit-card sized diamond hone at 600 grit, this is the best grit for carbide; 300 grit is more appropriate for high-speed steel (HSS).

Notice we’re saying “maintenance” and not “sharpening”. Router bit maintenance is about removing any imperfections from the flat side of the carbide tip, that’s it. It requires very little force; just lightly rubbing the diamond hone across the tip face ten times, and then doing the exact same motion on the other side.

We don’t want to sharpen the profile of the tip as it’ll change the cutting shape. Likewise, if we use too much force downwards on the carbide, or if we grind the diamond hone across the face of the bit too many times, there’s the risk of changing the router bit profile.

Storing Your Router Bits

Router bit maintenance is all for nothing if you don’t store the bits properly. Buy, or build, a router bit tray to keep these very valuable tools safe. Store them in a place with as little moisture as possible. If you’re buying the bits individually, store them in the plastic cases provided. Compared to HHS, carbide is very brittle. Left loose in a drawer, or accidentally dropped on the floor, carbide will break.

Take good care of your router bits and they’ll last a very long time. Wishing you the best of luck on all of your projects from the folks here at POWERTEC.

|

|

|

|||

|

|

|

|