Guide to Blade Length and Compatibility

POWERTEC on Aug 17th 2025

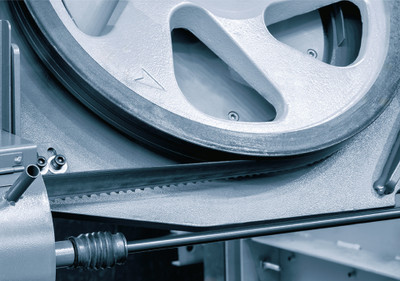

Selecting the correct bandsaw blade length is essential for optimal performance

and precise cuts. Each band saw is designed for a specific blade length, which

corresponds to the size and configuration of its wheels and tensioning system. Using

the wrong length can cause poor tensioning, uneven cuts, or even damage to your

machine. Blade length refers to the total loop of the blade and is usually specified in

your band saw’s user manual. If you’re unsure of the exact length, you can measure it

by following a few simple steps.

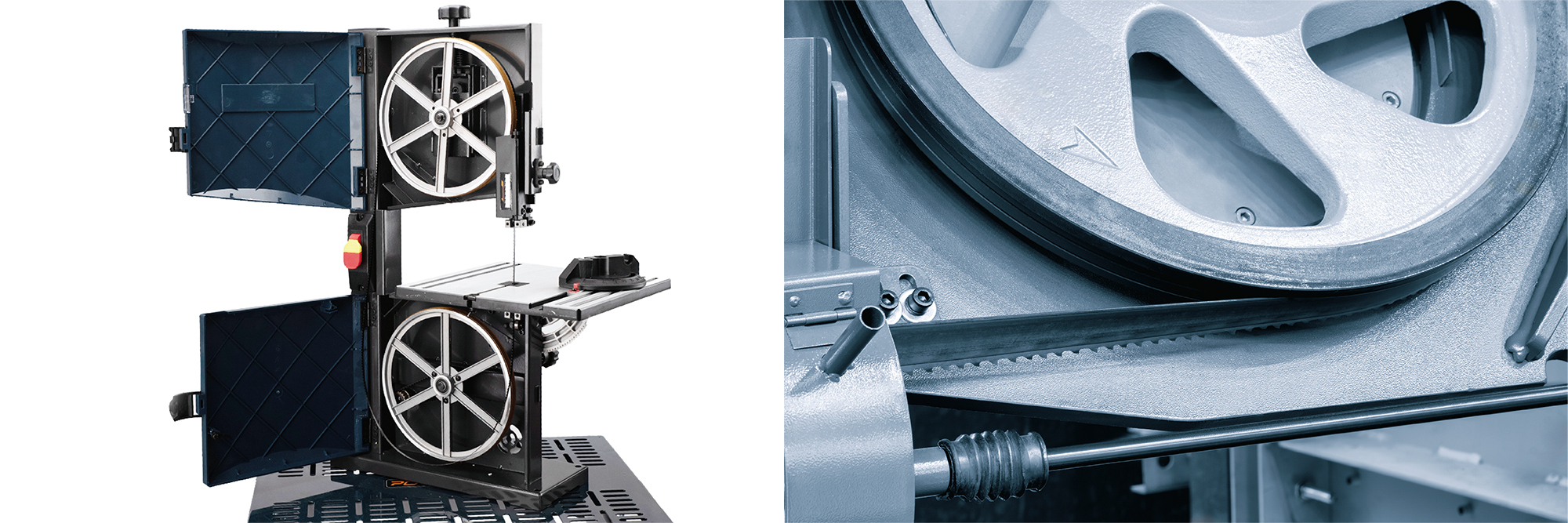

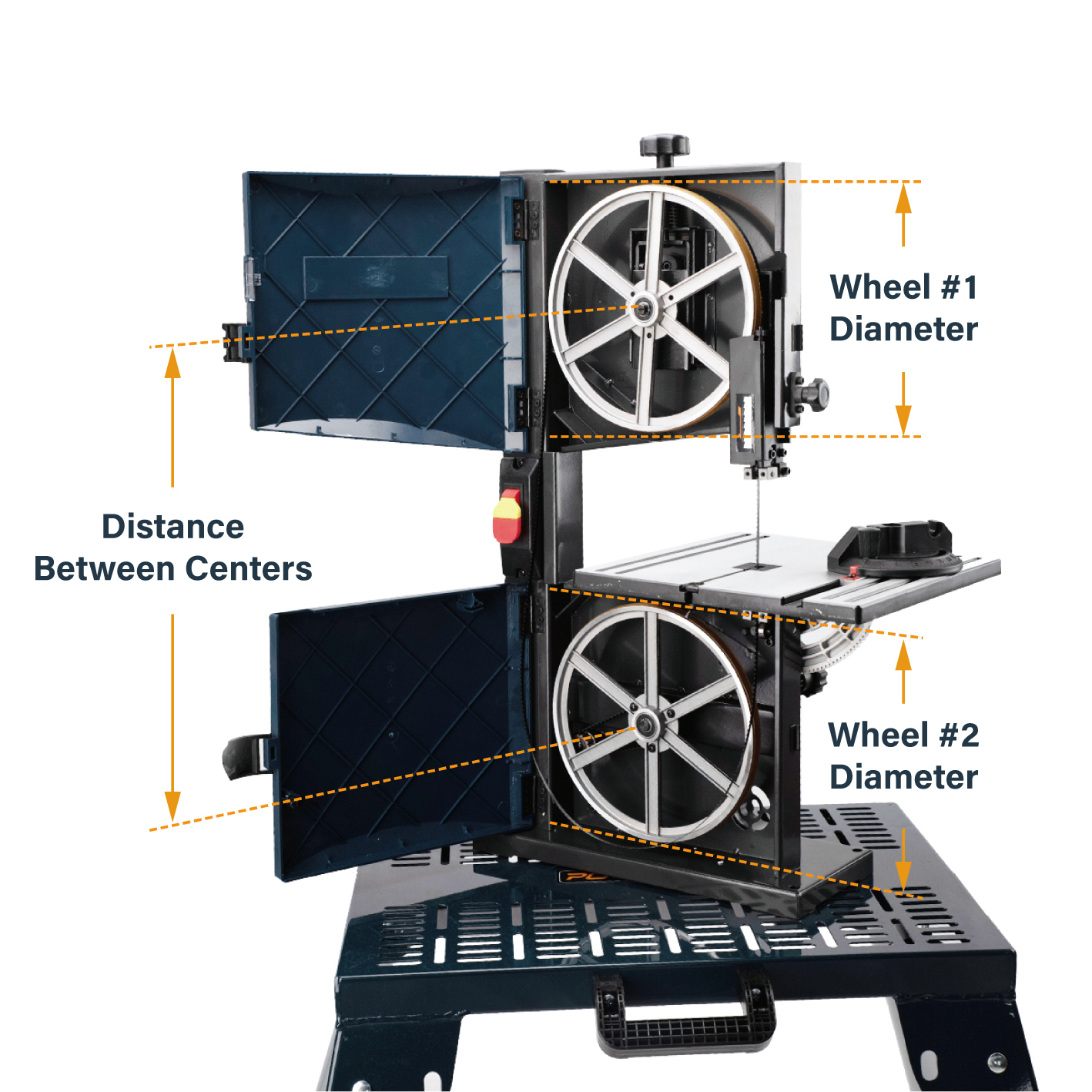

To determine your blade length manually, first measure the distance between the

centers of your band saw wheels when fully tensioned. Add the diameter of both wheels

and multiply by 3.14 (π) to estimate the total circumference of the blade path. Most band

saws fall within standard blade lengths—such as 56-7/8", 80", or 105"—but always

verify compatibility with your machine. POWERTEC offers a wide range of blade lengths

to fit compact, tabletop, and industrial band saws alike, ensuring you’ll find the perfect

match.

|

Compatibility goes beyond length—it’s about how your blade fits your machine’s tensioning system and wheel size. Bandsaws are designed to handle specific ranges of blade widths and lengths. Smaller band saws with compact wheels typically require shorter blades, often under 80", while larger, industrial models can accommodate blades over 100". Additionally, wheel size impacts the type of blade you can use. Larger wheels allow for wider blades, which are better for straight cuts and resawing. Smaller wheels require narrower blades, making them ideal for tight curves but unsuitable for heavy-duty applications. |

|

Improper tensioning is a common problem when using an incorrect blade length. If the blade is too short, the tensioning mechanism may not engage properly, leading to unstable cuts. Conversely, a blade that’s too long can’t be tensioned correctly, causing blade drift or uneven cuts. Regularly check your band saw’s tensioning system and adjust as needed to ensure a snug, secure fit. POWERTEC blades are designed to meet the precise specifications of various machines, giving you confidence in their compatibility and performance. |

|

Choosing the right blade length ensures better results and extends the life of your equipment. A properly fitted blade delivers smooth, accurate cuts while reducing wear and tear on your band saw’s components. POWERTEC’s comprehensive range of lengths is compatible with a wide variety of band saw models, from hobbyist machines to professional-grade equipment. Whether you’re working on a detailed woodworking project or resawing thick materials, selecting the correct blade length is the first step toward success. |

|

The right blade length isn’t just a technical requirement—it’s the foundation for achieving precision and efficiency in your work. Take the time to measure your machine’s specifications or consult your user manual to find the perfect fit. With POWERTEC’s high-quality blades, you can count on consistency and durability every time you cut.

|

|

| Blade Length | Best Uses | Compatible Machines | Tips for Selection |

| 56-7/8" to 72" | Compact, hobbyist applications | Small band saws (e.g., benchtop models) | Verify length using manual or measure blade path manually. |

| 80" to 105" | Standard workshop projects | Medium-sized band saws | Suitable for general-purpose and light-duty resawing. |

| Over 105" | Industrial and heavy-duty applications | Large, professional-grade band saws | Ideal for thick materials and large-scale woodworking tasks. |