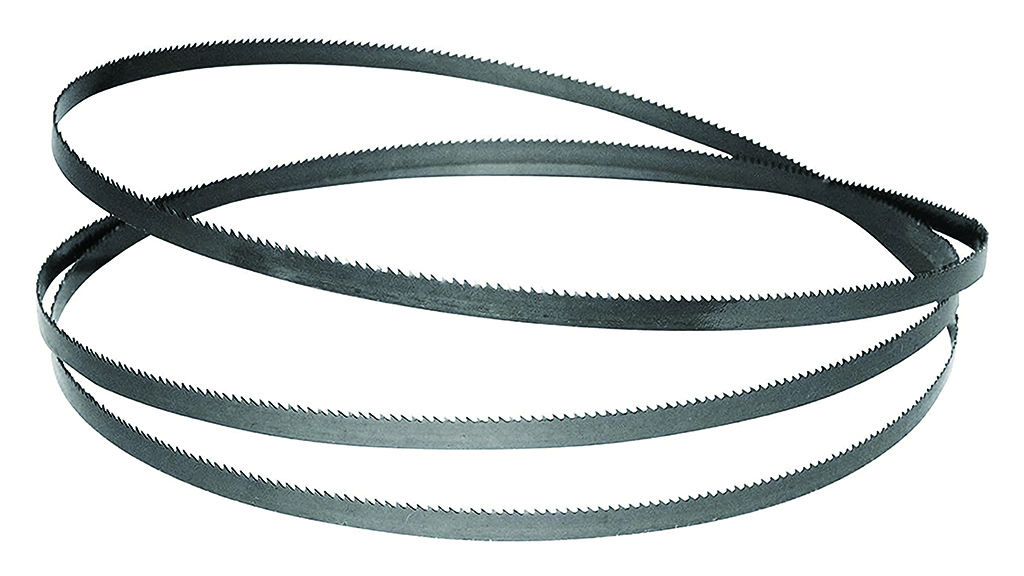

Choosing your Band Saw Blades: A Quick Guide

POWERTEC on Sep 8th 2025

Choosing the right bandsaw blade doesn’t have to be complicated. With so many options for materials, TPI, blade widths, and lengths, it’s easy to feel overwhelmed. But by breaking the process into manageable steps, you can confidently select the blade that matches your project needs. This guide condenses everything we’ve shown so far in our five band saw blogs and includes practical tools—charts and diagrams—to help you make the best choice.

Step 1: Match the Blade to Your Material

The material you’re cutting is the most important factor in blade selection. Different materials require different blade types:

• Wood and Plastics: Use carbon steel blades for their affordability and flexibility.

• Metals and Mixed Materials: Choose bi-metal blades for their durability and ability to handle tougher tasks.

|

|

| Material | Recommended Blade Type |

| Softwoods, hardwoods, plastics | Carbon Steel Blade |

| Metals, dense hardwoods, composites | Bi-Metal Blade |

Step 2: Choose TPI Based on Material Thickness

TPI (teeth per inch) affects cut speed and finish. Lower TPI blades are faster but rougher, ideal for thick materials. Higher TPI blades are slower but smoother, perfect for thin or delicate materia

| TPI Range | Best For | Examples |

| 3 - 6 TPI | Thick materials, rough cuts | Logs, beams, thick hardwoods |

| 8 - 14 TPI | General-purpose, balanced cuts | Plywood, plastics, medium woods |

| 18 - 24 TPI | Thin materials, smooth cuts | Veneers, plastics, soft metals |

|

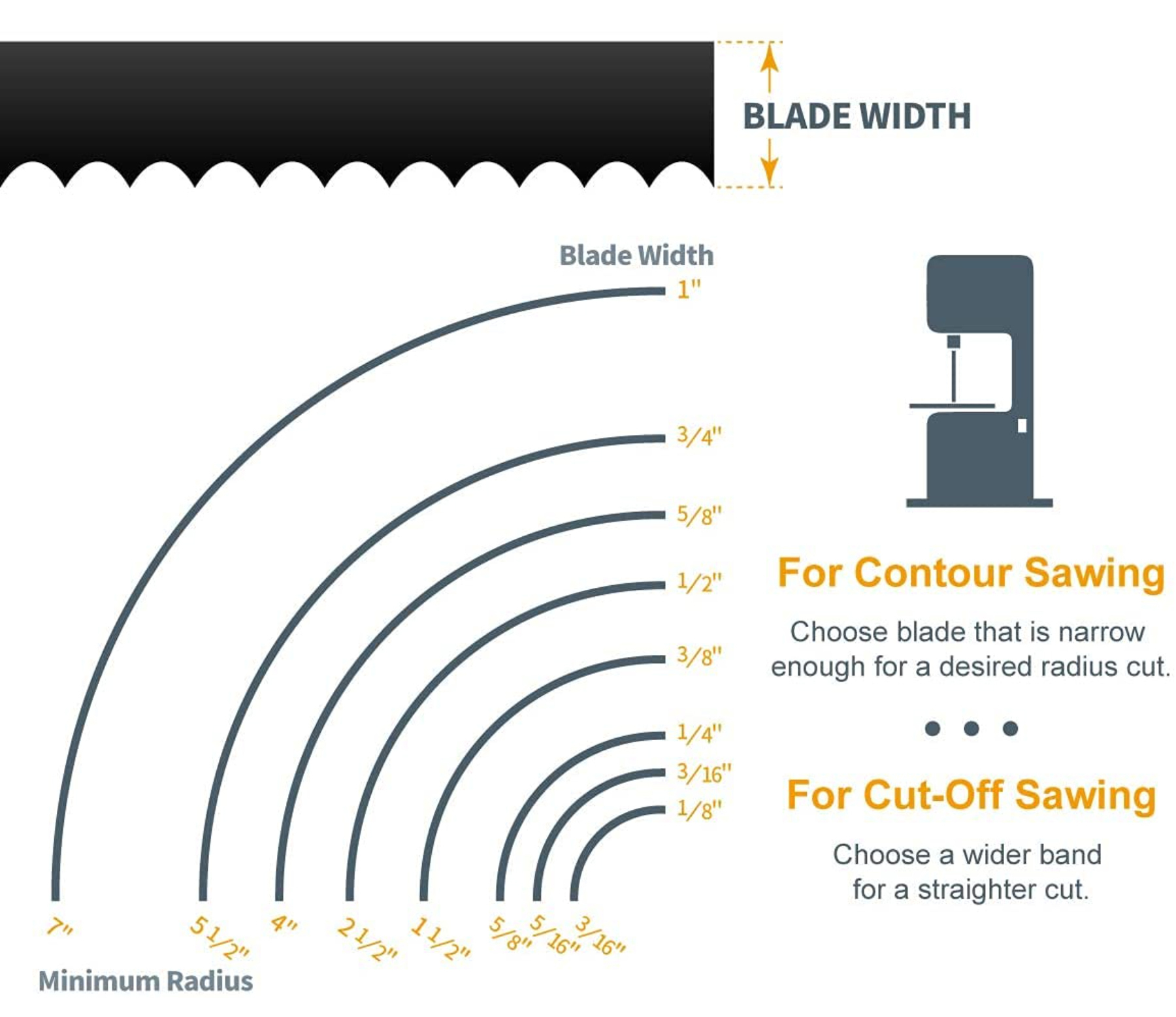

|

| Blade Width | Best Uses | Material Recommendations |

| 1/8"–1/4" | Tight curves, intricate patterns | Softwoods, thin plywood, plastics |

| 3/8"–1/2" | General-purpose, moderate curves | Medium-density woods, plastics |

| 3/4"+ | Straight cuts, resawing, heavy-duty | Hardwoods, dense composites |

|

|

Step 4: Ensure Length and Compatibility

Blade length must match your band saw’s specifications. Check your user manual or measure your blade path. Longer blades are for industrial machines; shorter ones fit compact models.

| Blade Length | Best Uses | Compatible Machines |

| 56-7/8" to 72" | Compact, hobbyist applications | Small band saws (e.g., benchtop models) |

| 80" to 105" | Standard workshop projects | Medium-sized band saws |

| Over 105" | Industrial and heavy-duty applications | Large, professional-grade band saws |

Final Thoughts

Selecting the right band saw blade is about balancing your project’s needs with your machine’s capabilities. By considering material, TPI, width, and length, you can find a blade that delivers the best results for your work. POWERTEC’s wide selection of blades ensures you’ll always have the perfect tool for the job. Ready to upgrade your cuts? Explore our collection today!

|

|

Flowchart: Your Blade Selection Made Easy

1. What Material Are You Cutting?

- Wood or Plastic → Carbon Steel Blade

- Metal or Mixed Materials → Bi-Metal Blade

2. What Type of Cut?

- Straight → Wide Blade (3/4"+)

- Curves → Narrow Blade (1/8"–1/4")

3. Material Thickness?

- Thick → Low TPI (3–6)

- Thin → High TPI (18–24)

4. Is the Blade Compatible with Your Machine?

- Check length and width specifications in your user manual.